How Transpring Automation Solutions Can Boost Your Profits in the Marijuana Vape Industry

How can you get more margins in the marijuana vape industry in 2025? Traditional manual labor can only take production so far. It is often slow, inconsistent, and prone to human error, which can result in wasted products, higher operational costs, and delays in getting products to market. Automation provides a solution by streamlining the production process and minimizing human intervention. For brands in the marijuana vape industry, this means faster, more accurate filling and capping of products, leading to improved efficiency and profitability. Transpring offers customized automation systems for filling and capping marijuana vape products. Their automated solutions are tailored to meet the specific needs of each product, including marijuana cartridges, marijuana vape pens, and vape pods, ensuring that every step from filling to sealing is performed with precision and speed.

Transpring Automation Solutions

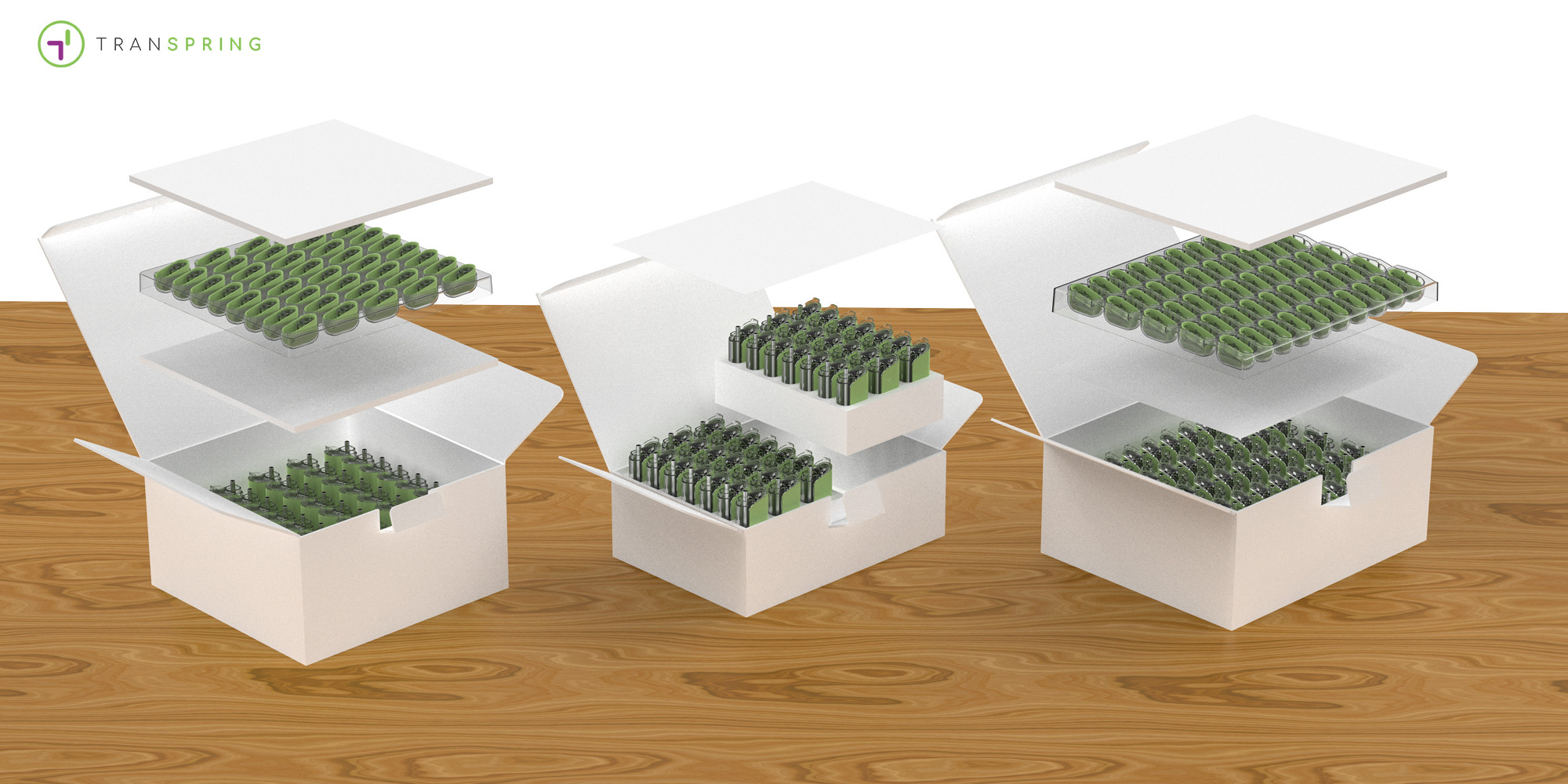

1. Pre-Loaded Components for Convenience

One of the standout features of Transpring’s automation systems is that cartridges, all-in-ones, and mouthpieces are pre-assembled and ready for automatic filling as soon as the packaging is opened. This minimizes the need for manual assembly, significantly speeding up the process. By eliminating the need to manually load components into the machine, you can focus more on other critical aspects of production, such as quality control and inventory management.

2. High-Capacity Filling and Capping

Transpring’s automation solutions are capable of filling and capping up to 10-100 units at a time. This scalability allows manufacturers to increase production speed and volume while maintaining high standards of quality. Whether you need to fulfill large orders or scale up for seasonal demand, Transpring’s system can handle the job, reducing the strain on your workforce and helping you stay competitive in a fast-paced market.

3. Precision with Every Cycle

One of the most critical aspects of marijuana vaporizer products is precision. The filling process must be accurate to ensure each cartridge is properly dosed, and the capping must be secure to prevent leaks or contamination. Transpring’s automation solutions are designed to meet these needs with high levels of precision. The jigs used in the system are meticulously designed to guide the body of the product and the mouthpiece into the correct position for filling and capping. This ensures that every unit is filled accurately and sealed securely, minimizing waste and maximizing product consistency.

4. Seamless Integration with Existing Processes

Transpring’s automated filling and capping systems are designed to be easily integrated into existing production lines. The systems are user-friendly, easy to operate, and can be customized to fit your unique production needs. Whether you want to test the market with a small batch or occupy the market with large-scale production, Transpring’s solutions can be adjusted to accommodate the specific requirements of your production line.

The Key Benefits of Transpring’s Automation Solutions

1. Increased Production Efficiency

The most immediate benefit of implementing Transpring’s automation solutions is the significant increase in production efficiency. With the ability to fill and cap up to 10-100 units at once, production times are drastically reduced. This allows you to produce more in less time, helping you meet rising demand and scale your operations quickly.

Moreover, automation reduces downtime and minimizes bottlenecks that typically arise from manual labor. The automated systems operate with minimal supervision, freeing up your staff for other tasks that require their expertise, such as quality control or packaging.

2. Improved Product Consistency and Quality

Consistency is key in the marijuana vape industry. Consumers expect a uniform experience with every use, and inconsistency in dosing or capping can lead to dissatisfaction or product returns. Transpring’s automated systems are engineered to ensure that each cartridge, all-in-one, or pod vape is filled with the exact amount of extract and sealed securely.

By automating the filling and capping processes, Transpring reduces the risk of human error that can lead to inconsistencies in product quality. This ensures that each unit meets the same high standard, which is essential for building a loyal customer base and avoiding costly recalls.

3. Cost Savings through Reduced Labor and Waste

Labor costs are a significant part of any manufacturing operation, and the marijuana vaporizer industry is no different. By automating the filling and capping processes, Transpring helps reduce the need for manual labor, cutting down on payroll expenses. This allows businesses to operate with a leaner workforce, reducing overhead while maintaining production capacity.

Furthermore, automation minimizes product waste. Manual filling can often result in spills, overfills, or underfills, all of which contribute to wasted products and higher production costs. Transpring’s precise filling and capping systems ensure that each unit is perfectly dosed, minimizing product waste and maximizing your bottom line.

4. Scalability and Flexibility

As your business grows, so does your production demand. Transpring’s automated solutions are scalable, meaning they can easily adapt to increased production volumes. Whether you need to ramp up production for a large batch or scale back during off-peak periods, these systems are flexible enough to accommodate changing needs.

The ability to handle multiple product types—whether cartridges, Marijuana vapes disposable, or pod systems—further enhances scalability. As new products are introduced to the market, Transpring’s systems can be quickly adapted to handle different configurations and sizes, giving your business the flexibility to diversify its product line.

5. Faster Time-to-Market

The speed at which you can produce and ship products has a direct impact on your bottom line. With Transpring’s automation solutions, you can significantly shorten production cycles. This faster turnaround time allows you to respond quickly to market trends, launch new products efficiently, and fulfill orders faster—giving you a competitive edge.

How Transpring Can Improve Your Profitability

The combination of increased efficiency, reduced labor costs, improved product consistency, and minimized waste all contribute to higher profit margins for marijuana vape brands. By automating key stages of production, you can scale your operations more quickly, meet growing demand, and maintain consistent product quality—all of which are essential for long-term success in the marijuana vape industry.

Moreover, automation frees up resources that can be reinvested in other areas of your business, such as marketing, R&D, or expanding your product portfolio. With Transpring’s customized automation solutions, you’re not just improving your production process—you’re positioning your business for sustainable growth and profitability.